Building with Hemp

Long used for textiles, food, and medicine, hemp — when mixed with lime and formed into panels and bricks — is increasingly being seen as a viable renewable building material for achieving carbon-neutral and healthy-building goals.

Hemp is a versatile crop: its seeds, fibers, shives (or hurd), leaves, and flowers have been used as litter for animal husbandry, for textiles, as oil for food, and as medicine. However, besides being added to plaster and concrete, hemp can also be used as an alternative building material, mainly as hemp fiberboard as well as hemp bricks. While hemp panels can be used for interior and exterior insulation, hemp bricks are suitable as non-load-bearing infill for exterior and partition walls in new buildings and renovations. Hemp-lime bricks are often used in niche projects, but this is likely to change with the current paradigm shift towards resource-conserving, climate-friendly and healthy materials and the accompanying rediscovery of traditional natural materials such as wood, clay, and straw.

The hurd extracted from hemp is mixed with water and natural lime to make 100% natural hemp bricks that are as hard as stone. Hemp bricks have numerous advantages: they are stable; they have acoustical and insulating properties; they do not burn or form mold; and rodents and vermin keep away from the hemp-lime mixture. Like other natural materials, hemp has a positive effect on indoor environments. Due to its ionizing effect, the material removes fine dust, fungi, and bacteria from the air, regulates room humidity, and, last but not least, has a pleasant odor.

As a purely natural material, hemp is renewable and thus also biodegradable, making it fit well into the currently much-praised circular economy. Used as bricks in timber construction, hemp scores points over pure solid wood construction, because hemp consumes less area for production than the same amount of wood. The plant grows, per suppliers' calculations, fifty times faster than trees — in just five months enough hemp would grow on one hectare to make a single-family house. Additionally, the use of hemp would even be climate-negative, since hemp stores CO2 to a high degree.

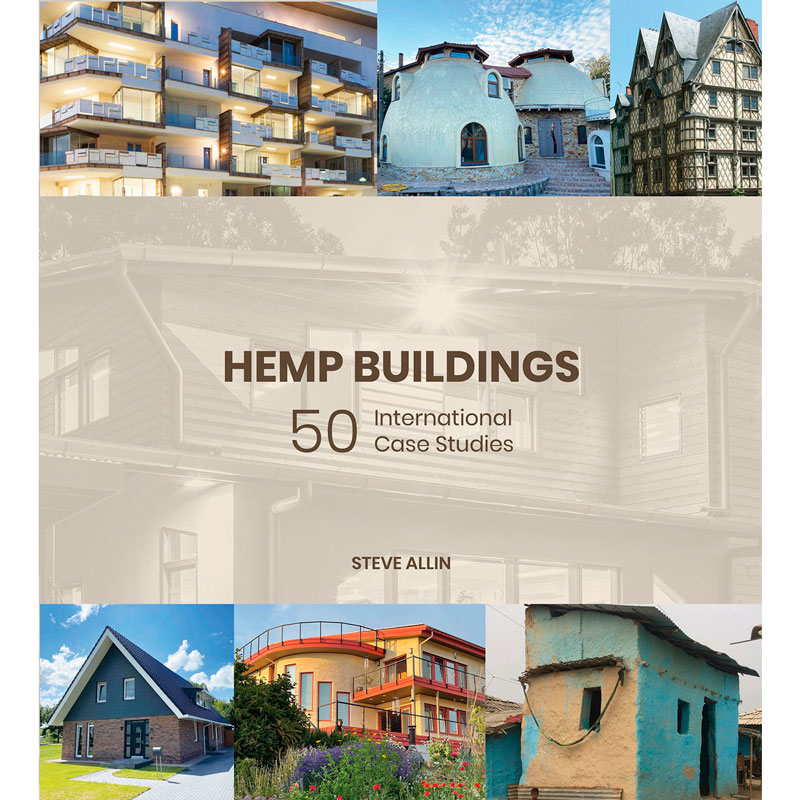

The benefits described in the above paragraphs, as pulled from Martina Metzner's article on hemp and lime published on German-Architects last year, are echoed in Steve Allin's new book Hemp Buildings: 50 International Case Studies. Allin, the founding director of the International Hemp Building Association, writes in the book's introduction: "From the ecological benefits on soils and wildlife that have already been documented through the cultivation of industrial hemp, to the improved air quality and comfort of interior climates in domestic dwellings and workspaces that have been built with natural materials, hemp provides so many solutions to the crises that currently face humanity."

The solutions spelled out by Allin stem from the ability of hemp, when "sown densely as a field crop in the same manner as grain," to grow quickly, smother competing weeds, reduce the need for herbicides, and improve the quality of farmland for a transition to an organic system of agriculture. Architecturally, the cellulose materials extracted from hemp, the hurd, when combined with a binder, "creates either a hemp fiber insulation matting which can be used as an alternative to mineral wool, or a bio-mineral composite known as hempcrete, which is used to provide an improved building envelope." Although lime, the binder used with hemp, emits more CO2 per ton than cement, once it combines to form hempcrete it "reabsorbs CO2 as it ages, becoming harder as it sequesters carbon."

Scientifically and agriculturally, hemp sounds like the ideal material for construction, one ripe for experimentation on the part of architects and builders. If the fifty projects assembled by Allin are any indication, that experimentation is taking place in the technical realm rather than through architectural forms; few of the projects are particularly eye-catching, though all of them provide beneficial lessons for designers, clients, and builders interested in exploring hemp-based applications. Some of the more architecturally interesting projects include: AMI Alvo Supermarket in Berlare, Belgium, by Martens Van Caimere Architecten, which combines CLT and hempcrete; Regional House in Edegham, Belgium, by BC Architects, an earth-brick structure housed in a former military hangar and therefore featuring exposed hempcrete; The Triangle in Swindon, England, by Glenn Howells Architects, a housing project featuring timber-framed units filled with cast hempcrete; and Case di Luce in Bisceglie, Italy, an apartment building designed, developed, and built by the Pedone family (Pedone Studio and Pedone Working), in which hemp is used in a variety of ways (plaster, precast blocks, and spray applied).

Many applications of hempcrete take the form of panels, encasing blocks, or non-load-bearing bricks, so one of the standout projects in Hemp Buildings from a technical perspective is the Harmless Home on Vancouver Island in British Columbia, Canada. Designed by Greenplan for Arno Keinonen, a marine engineer from Finland, and his wife, the house is a test-case for load-bearing blocks developed by Just BioFiber Structural Solutions, where Keinonen serves on the board of directors. According to the company's website, "Just BioFiber uses a patented composite structural frame inside each block that interlocks when stacked." The blocks resemble and function much like Lego bricks, with structural struts poking above the hempcrete to lock together, further strengthened by mortar and glue. Studs are located every 16 inches, as in conventional walls, and voids in the blocks allow for conduits. Strips, bolts and window/door trim are available, enabling the JBF blocks to become "an entire wall system." Although plaster finishes inside and outside make the Harmless House look conventional, its name signals its innovative merits, with the hempcrete blocks helping to create a home that is truly carbon-zero.

Hemp Buildings: 50 International Case Studies

Steve Allin

Foreword by Kehrt Reyher

245 x 230 mm

216 Páginas

350 Illustrations

Paperback

ISBN 9780955110979

Seedpress

Purchase this book